- What Is a Robot Joint Motor — and Why Selection Matters

- Start with the Load: Understanding Torque Requirements

- Motion Performance: Speed and Precision Demands

- Integration Constraints: Fitting Motors into Real Joints

- From Requirements to Selection Factors

- Joint-Based Motor Selection

- Step-by-Step Robot Joint Motor Guide for Selection

- Final Tips for Joint Motor Selection

How to Choose the Right Robot Joint Motor: Torque, Speed & Integration Explained

What Is a Robot Joint Motor — and Why Selection Matters

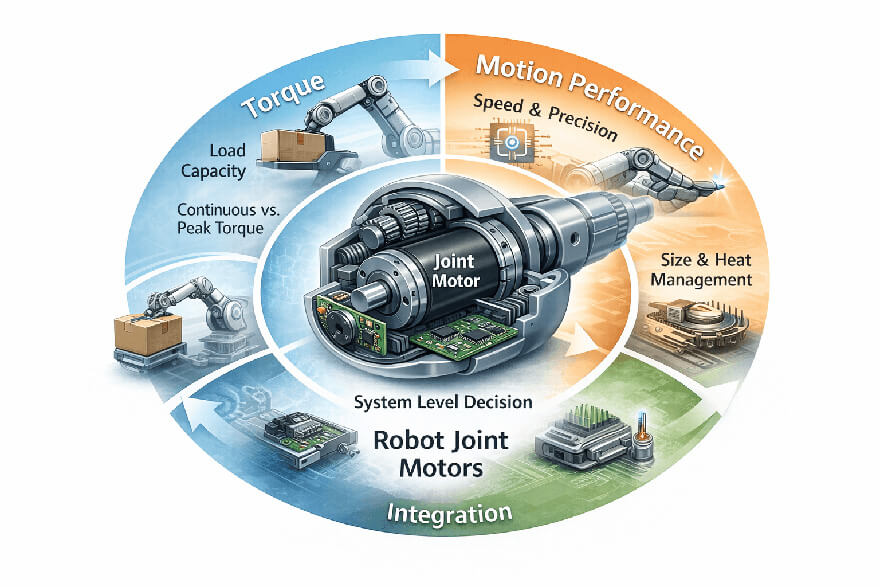

In a robotic system, motion is not created by motors alone, but by how motors are integrated into each joint. A robot joint motor converts electrical energy into controlled mechanical motion, enabling joints to rotate, lift, position, and respond with precision under load.

Unlike general-purpose motors, joint motors operate as part of a tightly coupled system.

They must work in coordination with:

Gear structures

Sensors and encoders

Controllers and control algorithms

Mechanical loads and joint geometry

As a result, their performance directly affects a robot's speed, accuracy, payload capacity, and long-term reliability.

For many engineers, motor selection may initially appear to be a straightforward parameter-matching task—choosing a motor that satisfies torque and speed requirements on paper. In real-world systems, however, joint motor selection has broader consequences.

An unsuitable motor can lead to:

Excessive heat generation

Unstable or oscillatory motion

Limited control accuracy

Structural redesigns later in development

For this reason, selecting a robot joint motor is not merely a component-level decision. It is a system-level choice that influences how efficiently the robot moves, how precisely it performs tasks, and how reliably it operates over time.

Before examining specific motor technologies or configurations, it is essential to understand what a robot joint actually demands from its motor in real operating conditions. These demands form the foundation for every selection decision that follows.

Start with the Load: Understanding Torque Requirements

(Why torque is always the first question in joint motor selection)

If a joint motor cannot reliably handle its load, no amount of speed, control tuning, or positioning accuracy can compensate for it. So,understanding both continuous and peak torque requirements is essential because a motor that meets only one of these may fail in actual operation.

Two torque values matter in real applications:

Continuous torque reflects the load a joint can sustain over long periods without overheating. This is especially critical in service or industrial robots performing repetitive tasks for hours, where the robot joint motor operates continuously under load as part of an industrial robot drive system. Motors that fall short here often suffer from thermal stress, reduced lifespan, and inconsistent output.

Peak torque, by contrast, represents short-duration demands — starting motion under load, rapid acceleration, or responding to sudden resistance. Ignoring peak torque can lead to stalling, vibration, or mechanical shock within the joint.

Torque demand is rarely static. In high-speed or precision applications, it fluctuates constantly as loads shift and motion profiles change. Motors must respond smoothly to these variations to maintain stability and accuracy.

Motion Performance: Speed and Precision Demands

(How fast a joint moves — and how accurately it arrives)

Once torque is sufficient, the real challenge becomes how fast a joint moves—and how accurately it reaches its target. These parameters determine not only the robot's efficiency but also the quality and consistency of its tasks.

High-speed joints enable faster cycle times in industrial robots and more natural responses in service robots. However, speed without sufficient torque control often introduces overshoot, vibration, or mechanical stress — reinforcing why torque analysis must come first.

Precision is equally critical. Positional accuracy ensures the end effector — whether a gripper, tool, or sensor — reaches its target consistently. In collaborative or medical robot applications, this requirement is ultimately borne by the joint motor itself, where even minor deviations in motor output can directly affect safety, repeatability, or clinical outcomes. Precision therefore depends not only on the mechanical structure of the robot, but on the performance of the collaborative or medical robot motor — particularly encoder resolution, control bandwidth, and motion smoothness.

Acceleration and deceleration further complicate matters. Load changes during motion affect both speed stability and positioning accuracy. Motors must handle these dynamics smoothly to maintain consistent performance.

Key takeaway: Speed defines how fast a joint moves — precision defines how trustworthy that motion is.

Integration Constraints: Fitting Motors into Real Joints

(Why performance alone is never enough)

Many motors look ideal on paper, yet fail once they are placed inside a real robotic joint. Even the best-performing motor can fail to deliver results if it cannot be properly integrated into the robotic system.

Size and form factor are critical in joint motor design. The motor must physically fit within the joint housing while leaving space for gears, encoders, wiring, and thermal paths. These constraints are especially pronounced in humanoid robot joint motors, where multiple degrees of freedom are packed into compact, human-scale limbs. Limited joint volume places strict limits on motor diameter and length, making torque density and integration efficiency far more important than raw size. As a result, humanoid robot motors must deliver sufficient continuous and peak torque within a highly constrained envelope, without compromising thermal stability or motion smoothness.

Mounting and alignment also matter. Proper alignment ensures that the motor transfers force efficiently and avoids unwanted stresses that can lead to wear or mechanical failure. Designers must also consider ease of assembly and maintenance when selecting motor dimensions and interface options.

Thermal management is another factor linked to integration. Motors generate heat, and sufficient space, airflow, or cooling mechanisms must be accounted for. A motor that meets torque and speed requirements but overheats in a confined joint may degrade rapidly, affecting both performance and longevity.

By analyzing these integration constraints alongside performance requirements, engineers can narrow down motor options effectively. This sets the stage for the next step: understanding how these requirements shape the actual selection process, which will be the focus of the next chapter.

From Requirements to Selection Factors

Now that we've explored the key influences on joint performance—torque, motion characteristics, and integration constraints—the next step is understanding how to turn these factors into concrete motor selection decisions.

Not all joints are created equal, and the relative importance of each factor varies depending on the application:

Torque vs. Speed

Joints carrying heavy loads, like shoulders in industrial arms, prioritize torque over speed.

Conversely, wrist or end-effector joints often require high-speed motion with moderate torque.

Understanding the trade-off helps narrow down motor choices effectively.

Precision Requirements

Tasks demanding exact positioning, such as assembly or delicate manipulation, make precision and smooth motion control critical.

Other joints performing broader movements may tolerate lower positional accuracy, which allows for more compact or lower-cost motors.

Integration Constraints

Space, alignment, and thermal considerations influence what motors can physically fit and operate reliably.

Compact form factors are essential for tightly packed wrist joints, whereas larger shoulder joints can accommodate bigger motors.

By weighing these factors together, engineers can define a joint-specific selection strategy instead of treating every joint the same. This approach ensures that the chosen motor not only meets performance needs but also fits the mechanical and operational constraints.

With this framework in mind, the next chapter will apply these principles to specific joint types, showing how to choose appropriate motors for shoulders, elbows, and wrists, with practical examples that translate theory into real-world selection.

Joint-Based Motor Selection

With selection strategies in place, it's time to see how they apply to different robot joints. Each joint has unique motion requirements, load demands, and integration constraints, which influence the choice of motor.

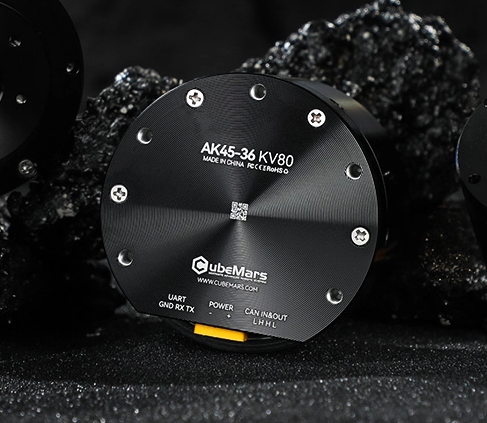

| Joint | Typical Tasks | Key Motor Requirements | Selection Strategy | Example Product |

|---|---|---|---|---|

| Shoulder | Large-range rotation, heavy payload | High torque, smooth acceleration, reliability under load | Prioritize torque and robustness; compactness is secondary |

|

| Elbow | Moderate load, precise positioning, repeated motion | Accuracy, smooth motion, moderate torque | Balance precision and torque; consider duty cycle and responsiveness |

|

| Wrist & End-Effector | Fast rotations, fine manipulation, high-speed adjustments | High-speed response, low inertia, compact size | Prioritize speed and precision; torque requirements usually lower than shoulder/elbow |

Step-by-Step Robot Joint Motor Guide for Selection

To make the selection process more approachable, here's a simplified workflow engineers can follow:

1. Define Joint Requirements

Torque (continuous and peak)

Speed and acceleration

Precision and positional accuracy

Integration constraints (space, alignment, cooling)

2. Identify Trade-Offs

Heavy-load joints → prioritize torque

Fast-moving joints → prioritize speed

Precision-critical joints → prioritize smooth motion and encoder quality

3. Shortlist Motors

Compare datasheets for torque, speed, and dimensions

Check compatibility with controllers and gearboxes

4. Validate Against Application

Ensure thermal limits, duty cycle, and expected payload are met

Consider reliability under repetitive or continuous operation

5. Map the Selection to Specific Joints

Shoulder Joint Motor → typically require high continuous torque and thermal stability to support sustained loads

Elbow Joint Motor → demand a balance between torque, speed, and compact integration

Wrist Joint Motor → prioritize fast response, high peak torque, and precise control

Following these steps ensures engineers move from theory to practical, joint-specific motor choices without missing critical factors.

Final Tips for Joint Motor Selection

Always start with torque: If the motor can't handle the load, speed and precision won't matter.

Consider the full system: Encoders, gearboxes, and mechanical integration affect performance.

Don't over-spec: Oversized motors increase cost, weight, and complexity.

Think ahead: Continuous operation, thermal limits, and duty cycles determine long-term reliability.

Leverage real examples: Reviewing similar applications and existing motor solutions helps validate your choices.

By understanding the specific needs of each joint, weighing torque, speed, precision, and integration constraints, and following a step-by-step selection workflow, this guide aims to help you select the right motor, enabling your robot to move more efficiently, accurately, and reliably.