- The Key Challenge: Balancing Weight and Control in Upper-Limb Exoskeletons

- Advantages of Feedforward Control

- High-Performance Robot Motors: The Heart of Exoskeleton Actuation

- AK60-6 V1.1 KV80 Robotic Actuator

- AK80-9 KV100 High Torque Robotic Actuator

- System Architecture and Implementation

- Experimental Validation and Future Applications

- FAQ

Exoskeleton Motors Power Breakthroughs in Upper-Limb Technology

In recent years, exoskeleton robots have emerged as a transformative technology, enhancing human mobility, supporting rehabilitation, and boosting industrial productivity. These wearable robotic systems provide precise motion assistance, helping users extend physical capabilities, reduce fatigue, and improve quality of life for individuals with movement impairments.

Among various exoskeleton applications, upper-limb exoskeletons present a unique challenge. With complex joint kinematics and wide ranges of motion, achieving accurate control while maintaining lightweight and ergonomic designs has become a critical focus for researchers and engineers.

Today, we will guide you through a paper from Ruhr West University of Applied Sciences.

The Key Challenge: Balancing Weight and Control in Upper-Limb Exoskeletons

Traditional exoskeleton control strategies often rely on feedback mechanisms, such as PID controllers, which use external sensors to correct positional errors in real time. While effective, these solutions increase system complexity, weight, and power consumption.

To address this, the team developed an active gravity compensation system based on feedforward control. By leveraging only the internal position sensors of the motors, the system can predict and counteract gravitational torque without additional external sensors. This approach not only simplifies the hardware architecture but also improves dynamic performance and ergonomic compatibility — aligning with CubeMars’ philosophy of precision actuation for wearable robotics.

Advantages of Feedforward Control

Feedforward control does not rely on error feedback; instead, it calculates the required compensation torque in advance. This enables highly responsive and smooth movement, minimizing latency during dynamic actions.

Testing shows that the system maintains stable posture even under minimal friction conditions and performs reliably across multiple movement transitions. For rehabilitation and industrial assistance, this translates to reduced muscular effort, safer operation, and a more natural human-robot interaction.

High-Performance Robot Motors: The Heart of Exoskeleton Actuation

Exoskeleton Motor performance is critical for wearable robotics. In our upper-limb exoskeleton system, each side is equipped with CubeMars high power-to-weight exoskeleton motors, including:

AK60-6 V1.1 KV80 Robotic Actuator

24V Rated Voltage

9 N·m Peak Torque

315g weight

Optimized for lightweight robotic and exoskeleton applications

AK80-9 KV100 High Torque Robotic Actuator

48V Rated Voltage

18 N·m Peak Torque

Designed for higher load joints with reliable, precise output

These robot motors combine high torque density, lightweight design, and built-in driver circuits, making them ideal for exoskeleton robots, robotic arms, and rehabilitation devices. Integrated with feedforward control, CubeMars motors enable near-instant torque response for active gravity compensation, supporting natural and ergonomic movement.

System Architecture and Implementation

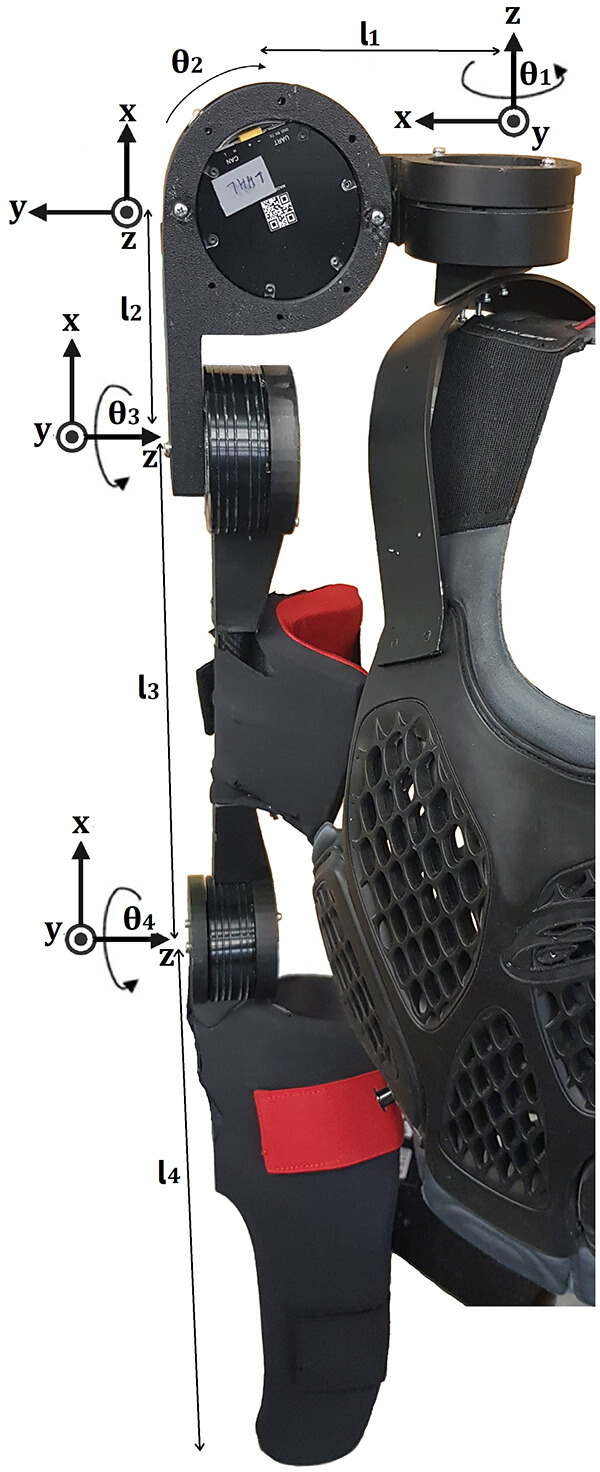

The exoskeleton features a four-degree-of-freedom (4-DOF) design, accurately replicating natural shoulder and elbow movements in three-dimensional space. The control system is built on an ATmega328P microcontroller (Arduino Uno) and communicates with motors via the CAN bus protocol.

Power is supplied by a TATTU 22.2V 222Wh smart LiPo battery, providing high energy density and long runtime. With a total weight of approximately 8 kg, the system is comfortable for extended wear while maintaining excellent ergonomic compatibility.

Experimental Validation and Future Applications

Test results demonstrate that the active gravity compensation system allows the exoskeleton to maintain posture across a wide range of positions without noticeable delay or drift. During dynamic motions, joint response is precise and smooth, showcasing the benefits of combining feedforward control with high-performance CubeMars exoskeleton motors.

Looking ahead, this technology is ideal for upper-limb rehabilitation robots, industrial assistive exoskeletons, and collaborative robotic arms. By integrating CubeMars’ high power-to-weight motors with a lightweight, ergonomic design, this system offers a practical and efficient solution for wearable robotics, enhancing human mobility and supporting real-world applications.

FAQ

What is the key innovation in this upper-limb exoskeleton technology?

The breakthrough lies in using feedforward-controlled active gravity compensation that eliminates the need for external sensors. The system leverages only internal motor position sensors to predict and counteract gravitational torque, significantly reducing hardware complexity and weight while improving performance.

How does feedforward control differ from traditional control methods?

Unlike traditional feedback control (like PID controllers) that rely on external sensors and error correction, feedforward control calculates the required compensation torque in advance. This enables highly responsive movement with minimal latency and eliminates the need for additional external sensors.

What specific motors are used in this exoskeleton system?

The system uses CubeMars high-performance exoskeleton motors including the AK60-6 V1.1 (9 N·m peak torque, 315g weight) and AK80-9 (18 N·m peak torque) models. These motors feature high torque density, lightweight design, and built-in driver circuits optimized for exoskeleton applications.

What are the main applications for this technology?

This technology is ideal for upper-limb rehabilitation robots, industrial assistive exoskeletons, and collaborative robotic arms. It enhances human mobility, reduces muscular effort, and provides safer operation with more natural human-robot interaction.

What are the system specifications and performance results?

The 4-DOF exoskeleton weighs approximately 8kg and uses an ATmega328P microcontroller with CAN bus communication. Testing shows stable posture maintenance across wide position ranges, precise joint responses, and smooth dynamic motions without noticeable delay or drift.