the entirely redesigned RO Series

UNVEILING A

NEW ICON

ULTRA-LOW COGGING TORQUE

50

LARGE HOLLOW

THROUGH-HOLE DESIGN

The CubeMars RO80‑KV105 Standard is a high-performance frameless outrunner torque motor from the RO series, engineered as a precision drive solution for robotic joints, exoskeletons, and other demanding electromechanical systems.

Rated at 48 V, it features an ultra-low cogging torque design and a large-diameter hollow shaft—enabling easy routing of wiring or direct integration with drive shafts and gearboxes. Equipped as standard with Hall sensors and a temperature sensor, it delivers precise rotor position feedback and real-time thermal monitoring for enhanced control accuracy and system safety.

With a continuous torque of 1.3 N·m, peak torque up to 4 N·m, and a total weight of only 352 g, the RO80‑KV105 is optimized for applications where space is limited but high responsiveness, smooth motion, and exceptional reliability are critical—including exoskeletons, collaborative robot arms (cobot), medical and aerospace robotics, and more.

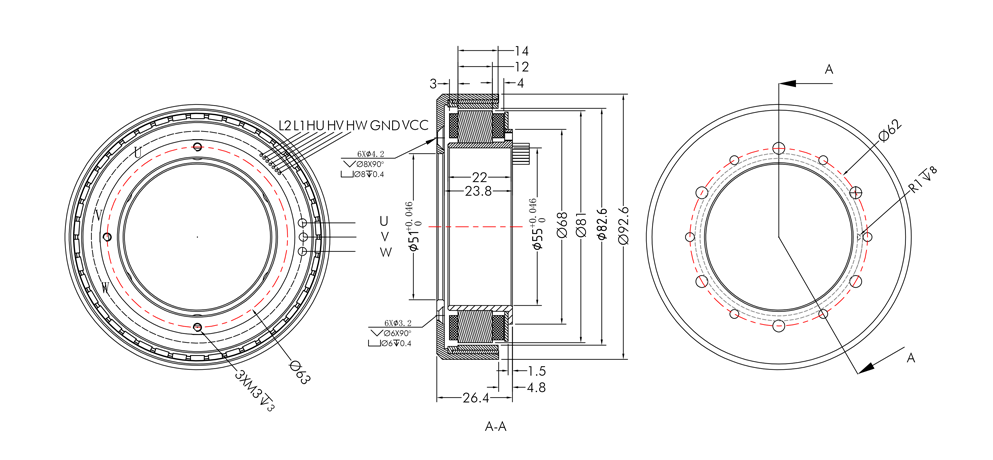

Motor Dimensions: Φ92.6 × 26.4 mm

Weight: 352 g

Peak Torque: 4 N·m

No-Load Speed: 5040 rpm

Ultra-Low Cogging Torque: Cogging torque reduced by ~50% compared to conventional motors, ensuring exceptionally smooth operation at low speeds and during start-up

Large Hollow Bore Design: Generous central aperture supports passage of signal/power cables or direct coupling with output shafts and harmonic drives—greatly enhancing mechanical integration flexibility

Integrated Hall + Temperature Sensors: Enables accurate commutation and real-time thermal protection, improving overall system reliability and operational safety

Aluminum Alloy Housing + Compact Form Factor: Lightweight yet rugged aluminum casing offers excellent corrosion and impact resistance; total mass of ~352 g makes it ideal for space-constrained installations

Broad Application Compatibility: Well-suited for exoskeleton robots, collaborative arms, medical/aerospace robotics, quadrupedal platforms, and AGV wheel-drive systems

RO80‑KV105 Standard Hall-with Frameless Outrunner Torque Motor ×1

Certificate of Conformance ×1

| RO80 KV105 Standard Version |

|

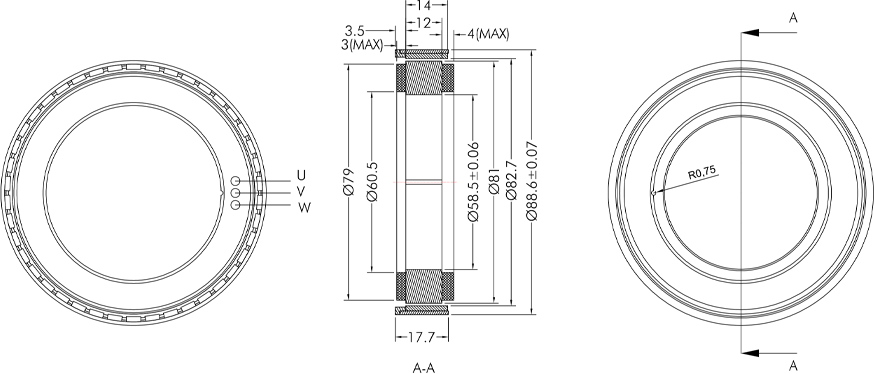

| RO80 KV105 Lite Version |

|

| RO80 KV105 Standard Version | |||

| Application | Cobot Arm | Insulation Class | F |

| Driving Way | FOC | Insulation High-Voltage | 500V |

| Operation Ambient Temperature | -20℃~50℃ | Insulation Resistance | 10MΩ |

| Winding Type | delta | Cogging Torque | 24N.mm |

| Pole Pairs | 21 | Inertia | 2612gcm² |

| Maximum Torque Weight Ratio | 11.36Nm/kg | Weight | 352g |

| Rotor Weight | 148g | Stator Weight | 204g |

| Hall Temperature Sensor Wire | 30#AWSilicone Wire100±5mm Tinning5±2mm | Lead-Out | Three-Phase Motor Lead-Out: Enameled Wire Straight Out 100±5mm Tinned5±2mm |

| Three-Phasewire | 3.5mm | ||

| RO80 KV105 Lite Version | |||

| Application | CobotArm | Insulation Class | F |

| Driving Way | FOC | Insulation High-Voltage | 500V |

| Operation Ambient Temperature | -20℃~50℃ | Insulation Resistance | 10MΩ |

| Winding Type | delta | Cogging Torque | 24N.mm |

| Pole Pairs | 21 | Inertia | 1600gcm² |

| Rotor Weight | 85g | Weight | 265g |

| Maximum Height of Enameled WireBulge | 6mm | Stator Weight | 180g |

| Three-Phasewire | 3.5mm | Lead-Out | Three-Phase Motor Lead-Out: Enameled Wire Straight Out 100±5mm Tinned 5±2mm |

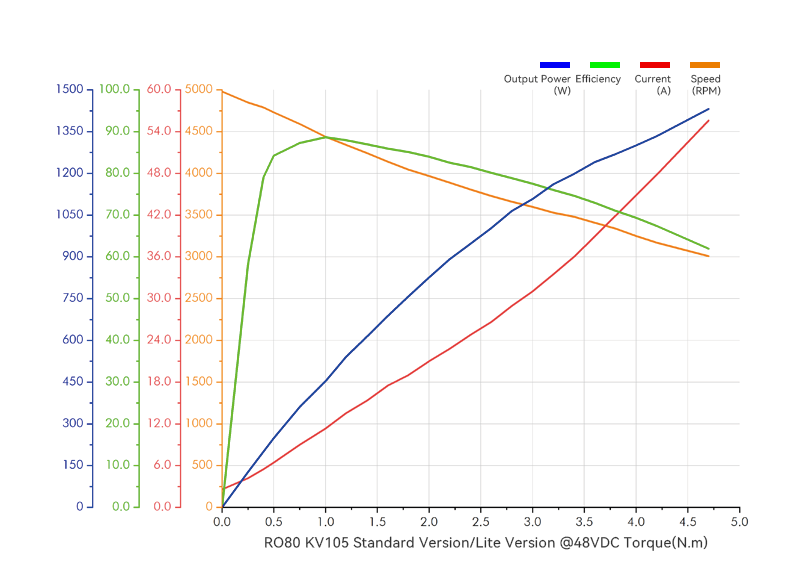

| Electric Parameters | |||

| Rated Voltage | 48V | Ke | 9.07V/krpm |

| No-Load Speed | 5040rpm | Phase To Phase Resistance | 120mΩ |

| Rated Torque | 1.3Nm | Phase To Phase Inductance | 103μH |

| Rated Speed | 3600rpm | Km | 0.25Nm/√W |

| Rated Current | 15ADC | Mechanical Time Constant | 2.95ms |

| Peak Torque | 4Nm | Electrical Time Constant | 0.86ms |

| Peak Current | 50ADC | Kt | 0.087Nm/A |

| Kv | 105rpm/V | ||

RO Series Motor Installation Tutorial: Step-by-Step Video

Want to share your CubeMars experience or open-source work? Contact us—we’re open to more collaborations!